服务热线

021-31262005

美国尼科NICO进口第二代气动隔膜泵较前代虽然体积更小,但是所输出的流量及压力却更大,并且重新设计了配气阀,因为配气阀的新设计,使得产品在各种工况下的应用更可靠。换向阀为三向先导阀,可外部维护,换向阀无需润滑,并且铝制部件经阳极氧化处理并附环氧涂层,能抵御不洁空气的腐蚀(但是依然推荐在进气管路上加装气源处理附件,如气动三联件,以延长泵的使用寿命和提高使用稳定性)。

公称通径:10-100(mm)

流量范围:0-30(m3/h)

扬程范围:0-60(m)

功率范围:0.75kw-850kw

温度范围 :-40°C-200°C

1.无需灌引水,具有自吸能力;流道宽敞,通过性能好,允许通过颗粒直径可达10mm。抽送泥浆、杂质时,对泵磨损甚微;泵内无需润滑,无需冷却,即使空转,对泵也不会有影响;

2.扬程、流量可通过气阀开度实现无级调节,流量随背压(出口阻力)的变化而自动调整,适合中高粘度介质的抽送;而离心泵是以类水介质为设计基准,如果用于粘度稍高的介质,则需配套减速机或变频调速器,成本就大大提高了。

3.无需用电,可靠接地后不产生火花,在易燃易爆的环境中使用安全可靠且成本低;

4.结构简单、易损件少,后期维护成本低;体积小易于移动,占地面积小,无需地基,安装简便经济,可作为移动式物料输送泵;

5.剪切力低,对流体的搅动小,在输送物理、化学性质比较不稳定的介质中有较大的优势;

6.在工况恶劣的地方,如建筑工地、工矿企业的废水排放,由于污水的杂质多且成分复杂,管路易于堵塞,这样对于电泵来说就容易形成负载过高的情况,从而导致电机发热损坏,而气动隔膜泵可通过颗粒并且流量自动可调,管路阻塞时可自动停止直至恢复通畅而不损坏泵(该现象常常被称为气动隔膜泵“死机”,消除了引起“死机“”的原因后可恢复正常工作);

7.可输送较粘稠的介质(粘度≤10000cps),可浸没在介质中工作。

| 流量 Flow (L/min) | 扬程 Head (m) | 出口压力 Discharge Pressure (bar) | 吸程 Sucked Lift (m) | 允许通过 颗粒直径 Max Grain Diameter (mm) | 空气 消耗量 Max Air Consumption (L/min) | 供 气压力 Max Air Pressure (bar) | 进出口尺寸 Inlet and Outlet | |

| 丝扣 Threaded | 法兰 Flanged | |||||||

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 3/8" | |

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 1/2" | |

| 151 | 0~84 | 8.4 | 2-6 | ≤3.2 | ≤1120 | ≤7 | 1" | (25) |

| 378 | 0~84 | 8.4 | 2-6 | ≤4.8 | ≤2240 | ≤7 | 11/2" | (40) |

| 568 | 0~84 | 8.4 | 2-6 | ≤6.3 | ≤4900 | ≤7 | 2" | (50) |

| 568 | 0~69 | 6.9 | 2-6 | ≤8 | ≤4900 | ≤7 | 21/2" | (65) |

| 1041 | 0~84 | 8.4 | 2-6 | ≤10 | ≤9100 | ≤7 | (3") | 80 |

| 1041 | 0~69 | 6.9 | 2-6 | ≤10 | ≤9100 | ≤7 | 100 | |

| 注:以上性能参数为清水测试参数单位换算:1L/min=0.06m3/h | 1bar=0.1MPa 不带()为进出口默认形式,带()的为进出口可定制形式 | ||||||||

| 可选泵体材质 Available Material of Pump Body | 可选隔膜材质 Available Material of Diaphragm | ||||||||||

| 铸铁 Cast Iron | 铸钢 Cast Steel | 铝 合金 AL Alloy | 增强 聚丙烯 RPP | 不锈钢 Stainless Steel | 衬胶 Rubber Lining | 衬氟 Fluorin Lining | 聚醚 弹性体 Hytrel | 丁腈 橡胶 NBR | 氯丁 橡胶 Neoprene | 聚四氟乙烯 PTFE | 聚全氟乙烯 FEP |

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| PTFE=F4,FEP=F46 | PP和PVDF材质只有配FEP膜片 | |||||||||||

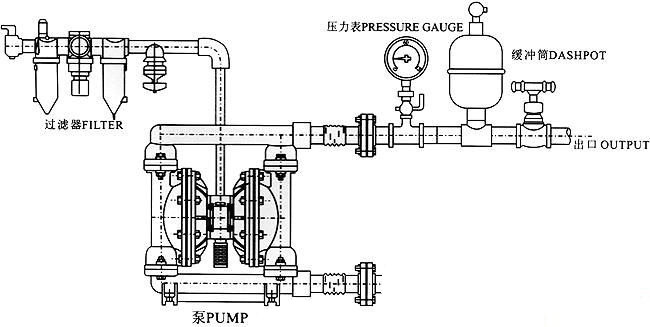

注:在使用进口第二代气动隔膜泵是要安装空气过滤器,以滤去压缩空气中的水分,并在泵的出口安装压力表,避免压力过高损害泵,在泵不工作时应及时清洗泵,避免因凝固损坏泵。

| 流量 Flow (L/min) | 扬程 Head (m) | 出口压力 Discharge Pressure (bar) | 吸程 Sucked Lift (m) | 允许通过 颗粒直径 Max Grain Diameter (mm) | 空气 消耗量 Max Air Consumption (L/min) | 供 气压力 Max Air Pressure (bar) | 进出口尺寸 Inlet and Outlet | |

| 丝扣 Threaded | 法兰 Flanged | |||||||

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 3/8" | |

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 1/2" | |

| 151 | 0~84 | 8.4 | 2-6 | ≤3.2 | ≤1120 | ≤7 | 1" | (25) |

| 378 | 0~84 | 8.4 | 2-6 | ≤4.8 | ≤2240 | ≤7 | 11/2" | (40) |

| 568 | 0~84 | 8.4 | 2-6 | ≤6.3 | ≤4900 | ≤7 | 2" | (50) |

| 568 | 0~69 | 6.9 | 2-6 | ≤8 | ≤4900 | ≤7 | 21/2" | (65) |

| 1041 | 0~84 | 8.4 | 2-6 | ≤10 | ≤9100 | ≤7 | (3") | 80 |

| 1041 | 0~69 | 6.9 | 2-6 | ≤10 | ≤9100 | ≤7 | 100 | |

| 注:以上性能参数为清水测试参数 单位换算:1L/min=0.06m3/h | 1bar=0.1MPa 不带()为进出口默认形式,带()的为进出口可定制形式 | ||||||||

| 流量 Flow (L/min) | 扬程 Head (m) | 出口压力 Discharge Pressure (bar) | 吸程 Sucked Lift (m) | 允许通过 颗粒直径 Max Grain Diameter (mm) | 空气 消耗量 Max Air Consumption (L/min) | 供 气压力 Max Air Pressure (bar) | 进出口尺寸 Inlet and Outlet | |

| 丝扣 Threaded | 法兰 Flanged | |||||||

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 3/8" | |

| 57 | 0~70 | 7 | 2-6 | ≤2.5 | ≤672 | ≤7 | 1/2" | |

| 151 | 0~84 | 8.4 | 2-6 | ≤3.2 | ≤1120 | ≤7 | 1" | (25) |

| 378 | 0~84 | 8.4 | 2-6 | ≤4.8 | ≤2240 | ≤7 | 11/2" | (40) |

| 568 | 0~84 | 8.4 | 2-6 | ≤6.3 | ≤4900 | ≤7 | 2" | (50) |

| 568 | 0~69 | 6.9 | 2-6 | ≤8 | ≤4900 | ≤7 | 21/2" | (65) |

| 1041 | 0~84 | 8.4 | 2-6 | ≤10 | ≤9100 | ≤7 | (3") | 80 |

| 1041 | 0~69 | 6.9 | 2-6 | ≤10 | ≤9100 | ≤7 | 100 | |

| 注:以上性能参数为清水测试参数 单位换算:1L/min=0.06m3/h | 1bar=0.1MPa 不带()为进出口默认形式,带()的为进出口可定制形式 | ||||||||

| 可选泵体材质 Available Material of Pump Body | 可选隔膜材质 Available Material of Diaphragm | ||||||||||

| 铸铁 Cast Iron | 铸钢 Cast Steel | 铝 合金 AL Alloy | 增强 聚丙烯 RPP | 不锈钢 Stainless Steel | 衬胶 Rubber Lining | 衬氟 Fluorin Lining | 聚醚 弹性体 Hytrel | 丁腈 橡胶 NBR | 氯丁 橡胶 Neoprene | 聚四氟乙烯 PTFE | 聚全氟乙烯 FEP |

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| ● | ● | ● | ● | ● | ● | ● | ● | ||||

| PTFE=F4,FEP=F46 | PP和PVDF材质只有配FEP膜片 | |||||||||||