服务热线

021-31262005

美国尼科NICO进口不锈钢化工泵为单级单吸悬臂式离心泵,其标记、额定性能点和尺寸等效采用国际标准ISO2858-1975(E)、美国尼科NICO进口不锈钢化工泵具有性能范围广、效率高、"三化"水平高和维修方便等特点,其效率比F型泵平均提高5%,是机械工业部确定取代F型耐腐蚀离心泵的节能、更新换代产品。供输送不含固体颗粒具有腐蚀性、粘度类似水的液体。

公称通径:25-300(mm)

流量范围:8-2600(m3/h)

扬程范围:7-150(m)

功率范围:1.5~18.5KW

转速范围:2900r/min

额定电压:DC24v、220v、380v,660v,1140v(DC、AC)

温度范围:-20℃~120℃

工作压力:≤1.6Mpa

泵体材质:铸铁、WCB、304、316、316L

进口不锈钢化工泵输送介质温度为-20℃~105℃,需要时采用双端面密封冷却装置,可输送介质温度为20℃~+280℃。适用于化工、石油、冶金、电力、造纸、食品、制药、环保、废水处理和合成纤维等行业用于输送各种腐蚀的或不允许污染的类似于水的介质。

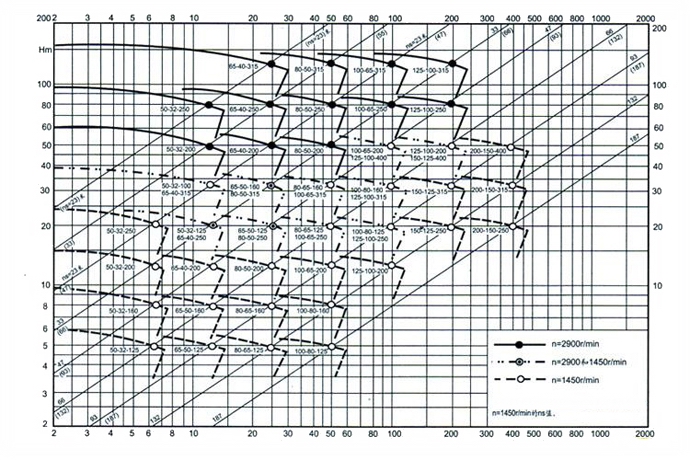

进口不锈钢化工泵的性能范围:进口不锈钢化工泵有29个基本型,其中22个双速(2900、1450r/min)经过A、B两种型式的叶轮直径切割变型后,达112个规格。

| 型号 | 转速 n | 流量 Q | 扬程 H | 效率 η | 功率 P | 必需汽蚀余量 | ||

| (r/min) | (m3/h) | (L/S) | (m) | (%) | 轴功率 | 电机功率 | (NPSH)r | |

| (KW) | (m) | |||||||

| BXNK50-32-125 | 2900 | 12.5 | 3.47 | 20 | 51 | 1.33 | 2.2 | 2 |

| 1450 | 6.3 | 1.75 | 5 | 45 | 0.19 | 0.55 | 2 | |

| BXNK50-32-125A | 2900 | 11.3 | 3.14 | 16.4 | 50 | 1.01 | 1.5 | 2 |

| 1450 | 5.7 | 1.58 | 4.1 | 43 | 0.15 | 0.55 | 2 | |

| BXNK50-32-160 | 2900 | 12.5 | 3.47 | 32 | 46 | 2.37 | 3 | 2 |

| 1450 | 6.3 | 1.75 | 8 | 40 | 0.34 | 0.55 | 2 | |

| BXNK50-32-160A | 2900 | 11.3 | 3.14 | 26.4 | 44 | 1.85 | 3 | 2 |

| 1450 | 5.7 | 1.58 | 6.6 | 37.1 | 0.28 | 0.55 | 2 | |

| BXNK50-32-200 | 2900 | 12.5 | 3.47 | 50 | 39 | 4.36 | 5.5 | 2 |

| 1450 | 6.3 | 1.75 | 12.5 | 33 | 0.65 | 1.1 | 2 | |

| BXNK50-32-200A | 2900 | 11.3 | 3.14 | 41 | 38 | 3.24 | 4 | 2 |

| 1450 | 5.7 | 1.58 | 10.3 | 31 | 0.52 | 0.75 | 2 | |

| BXNK50-32-250 | 2900 | 12.5 | 3.47 | 80 | 33 | 8.25 | 11 | 2 |

| 1450 | 6.3 | 1.75 | 20 | 27 | 1.27 | 2.2 | 2 | |

| BXNK50-32-250A | 2900 | 11.7 | 3.25 | 70 | 32 | 6.97 | 11 | 2 |

| 1450 | 5.9 | 1.64 | 17.5 | 25 | 1.25 | 1.5 | 2 | |

| BXNK50-32-250B | 2900 | 11 | 3.06 | 62 | 30 | 6.19 | 7.5 | 2 |

| BXNK65-50-125 | 2900 | 25 | 6.94 | 20 | 62 | 2.2 | 3 | 2 |

| 1450 | 12.5 | 3.47 | 5 | 55 | 0.31 | 0.55 | 2 | |

| BXNK65-50-125A | 2900 | 22.7 | 6.31 | 16.5 | 61 | 1.67 | 2.2 | 2 |

| 1450 | 11.3 | 3.14 | 4.1 | 54 | 0.23 | 0.55 | 2 | |

| BXNK65-50-160 | 2900 | 25 | 6.94 | 32 | 57 | 3.82 | 5.5 | 2 |

| 1450 | 12.5 | 3.47 | 8 | 51 | 0.53 | 0.75 | 2 | |

| BXNK65-50-160A | 2900 | 22.7 | 6.31 | 26.5 | 56 | 2.93 | 4 | 2 |

| 1450 | 11.3 | 3.14 | 6.6 | 49.6 | 0.41 | 0.55 | 2 | |

| BXNK65-40-200 | 2900 | 25 | 6.94 | 50 | 52 | 6.55 | 11 | 2 |

| 1450 | 12.5 | 3.47 | 12.5 | 46 | 0.93 | 1.5 | 2 | |

| BXNK65-40-200A | 2900 | 22.7 | 6.31 | 41 | 50 | 5.07 | 7.5 | 2 |

| 1450 | 11.3 | 3.14 | 10.3 | 44 | 0.72 | 1.1 | 2 | |

| BXNK65-40-250 | 2900 | 25 | 6.94 | 80 | 46 | 11.84 | 15 | 2 |

| 1450 | 12.5 | 3.47 | 20 | 39 | 1.75 | 3 | 2 | |

| BXNK65-40-250A | 2900 | 23.4 | 6.5 | 74.8 | 45 | 10.6 | 15 | 2 |

| 1450 | 11.7 | 3.25 | 17.5 | 37.9 | 1.47 | 2.2 | 2 | |

| BXNK65-40-250B | 2900 | 22 | 6.11 | 61.8 | 44 | 8.42 | 11 | 2 |

| BXNK65-40-315 | 2900 | 25 | 6.94 | 125 | 39 | 21.8 | 30 | 2 |

| 1450 | 12.5 | 3.47 | 32 | 33 | 3.3 | 5.5 | 2 | |

| BXNK65-40-315A | 2900 | 23.4 | 6.5 | 109.5 | 38 | 18.36 | 30 | 2 |

| 1450 | 11.7 | 3.25 | 28 | 33 | 2.71 | 4 | 2 | |

| BXNK65-40-315B | 2900 | 22 | 6.11 | 96.5 | 37 | 15.63 | 22 | 2 |

| BXNK80-65-125 | 2900 | 50 | 13.89 | 20 | 69 | 3.95 | 5.5 | 3 |

| 1450 | 25 | 6.94 | 5 | 64 | 0.53 | 0.75 | 2.5 | |

| BXNK80-65-125A | 2900 | 45.3 | 12.58 | 16.5 | 67 | 3.04 | 4 | 3 |

| 1450 | 22.7 | 6.31 | 4.1 | 62 | 0.41 | 0.55 | 2.5 | |

| BXNK80-65-160 | 2900 | 50 | 13.89 | 32 | 67 | 6.51 | 11 | 2.3 |

| 1450 | 25 | 6.94 | 8 | 62 | 0.88 | 1.5 | 2.3 | |

| BXNK80-65-160A | 2900 | 45.3 | 12.58 | 26.4 | 65 | 5.02 | 7.5 | 2.3 |

| 1450 | 22.7 | 6.31 | 6.6 | 60 | 0.68 | 1.1 | 2.3 | |

| BXNK80-50-200 | 2900 | 50 | 13.89 | 50 | 63 | 10.81 | 15 | 2.5 |

| 1450 | 25 | 6.94 | 12.5 | 57 | 1.49 | 2.2 | 2 | |

| BXNK80-50-200A | 2900 | 45.3 | 12.58 | 41 | 61 | 8.29 | 11 | 2.5 |

| 1450 | 22.7 | 6.31 | 10.3 | 56.1 | 1.14 | 2.2 | 2 | |

| BXNK80-50-250 | 2900 | 50 | 13.89 | 80 | 53 | 20.57 | 30 | 2.5 |

| 1450 | 25 | 6.94 | 20 | 50 | 2.72 | 5.5 | 2 | |

| BXNK80-50-250A | 2900 | 45.3 | 12.58 | 65.7 | 52 | 15.61 | 22 | 2.5 |

| 1450 | 22.7 | 6.31 | 16.4 | 49 | 2.07 | 3 | 2 | |

| BXNK80-50-315 | 2900 | 50 | 13.89 | 125 | 50 | 34.1 | 45 | 2.5 |

| 1450 | 25 | 6.94 | 32 | 48 | 4.54 | 7.5 | 2.5 | |

| BXNK80-50-315A | 2900 | 45.3 | 12.58 | 102.6 | 48 | 26.4 | 37 | 2.5 |

| 1450 | 22.7 | 6.31 | 25.7 | 46 | 3.46 | 5.5 | 2.5 | |

| BXNK100-80-125 | 2900 | 100 | 27.78 | 20 | 73 | 7.47 | 11 | 4.2 |

| 1450 | 50 | 13.89 | 5 | 69 | 0.99 | 1.5 | 3.4 | |

| BXNK100-80-125A | 2900 | 91.8 | 25.5 | 16.8 | 71 | 5.92 | 7.5 | 4.2 |

| 1450 | 45.9 | 12.75 | 4.2 | 67 | 0.78 | 1.1 | 3.4 | |

| BXNK100-80-160 | 2900 | 100 | 27.78 | 32 | 73 | 11.9 | 15 | 4.3 |

| 1450 | 50 | 13.89 | 8 | 68 | 1.58 | 2.2 | 3.4 | |

| BXNK100-80-160A | 2900 | 91 | 25.28 | 26.5 | 71 | 9.25 | 15 | 4.3 |

| 1450 | 45.5 | 12.64 | 6.6 | 67 | 1.22 | 1.5 | 3.4 | |

| BXNK100-65-200 | 2900 | 100 | 27.78 | 50 | 72 | 18.92 | 22 | 3.9 |

| 1450 | 50 | 13.89 | 12.5 | 68 | 2.5 | 3 | 2.5 | |

| BXNK100-65-200A | 2900 | 91 | 25.28 | 41.5 | 70 | 14.7 | 18.5 | 3.9 |

| 1450 | 45.5 | 12.64 | 10.3 | 66 | 1.93 | 3 | 2.5 | |

| BXNK100-65-250 | 2900 | 100 | 27.78 | 80 | 68 | 32.06 | 37 | 3.6 |

| 1450 | 50 | 13.89 | 20 | 63 | 4.33 | 5.5 | 2.5 | |

| BXNK100-65-250A | 2900 | 93.5 | 25.97 | 70 | 65 | 27.44 | 37 | 3.6 |

| 1450 | 45.5 | 12.64 | 17.4 | 61 | 3.53 | 5.5 | 2.5 | |

| BXNK100-65-250B | 2900 | 87.8 | 24.39 | 61.7 | 64 | 23.1 | 30 | 3.6 |

| BXNK100-65-315 | 2900 | 100 | 27.78 | 125 | 62 | 54.94 | 75 | 3.2 |

| 1450 | 50 | 13.89 | 32 | 58 | 7.52 | 11 | 2 | |

| BXNK100-65-315A | 2900 | 93.5 | 25.97 | 109 | 61 | 45.53 | 75 | 3.2 |

| 1450 | 46.5 | 12.92 | 28 | 56 | 6.33 | 11 | 2 | |

| BXNK100-65-315B | 2900 | 88 | 24.44 | 97 | 60 | 38.77 | 55 | 3.2 |

| BXNK125-100-200 | 2900 | 200 | 55.56 | 50 | 77 | 35.39 | 45 | 5 |

| 1450 | 100 | 27.78 | 12.5 | 73 | 4.66 | 7.5 | 2.9 | |

| BXNK125-100-200A | 2900 | 182 | 50.56 | 41.4 | 75 | 27.38 | 37 | 5 |

| 1450 | 91 | 25.28 | 10.3 | 71 | 3.6 | 5.5 | 2.9 | |

| BXNK125-100-250 | 2900 | 200 | 55.56 | 80 | 75 | 58.13 | 75 | 4.5 |

| 1450 | 100 | 27.78 | 20 | 72 | 7.56 | 11 | 2.3 | |

| BXNK125-100-250A | 2900 | 186.5 | 51.81 | 69.5 | 73 | 48.35 | 75 | 4.5 |

| 1450 | 93 | 25.83 | 17.4 | 70 | 6.29 | 11 | 2.3 | |

| BXNK125-100-250B | 2900 | 175.5 | 48.75 | 61.5 | 71 | 41.42 | 55 | 4.5 |

| BXNK125-100-315 | 2900 | 200 | 55.6 | 125 | 72 | 94.62 | 110 | 4.5 |

| 1450 | 100 | 27.8 | 32 | 65 | 13.42 | 22 | 2.5 | |

| BXNK125-100-315A | 2900 | 186.5 | 51.81 | 108.7 | 71 | 77.81 | 90 | 4.5 |

| 1450 | 93 | 25.83 | 27.2 | 64 | 10.77 | 15 | 2.5 | |

| BXNK125-10-400 | 1450 | 100 | 27.78 | 50 | 55 | 24.77 | 30 | 2.5 |

| BXNK125-100-400A | 1450 | 93 | 25.83 | 43.2 | 54 | 20.27 | 30 | 2.5 |

| BXNK150-125-250 | 1450 | 200 | 55.56 | 20 | 77 | 14.16 | 18.5 | 2.8 |

| BXNK150-125-250A | 1450 | 182 | 50.56 | 16.5 | 75 | 10.91 | 15 | 2.8 |

| BXNK150-125-315 | 1450 | 200 | 55.6 | 32 | 75 | 23.25 | 30 | 2.8 |

| BXNK150-125-315A | 1450 | 182 | 50.56 | 25.5 | 73 | 17.32 | 22 | 2.8 |

| BXNK150-125-315B | 1450 | 165 | 45.83 | 22 | 72 | 13.74 | 18.5 | 2.8 |

| BXNK150-125-400 | 1450 | 200 | 55.56 | 50 | 70 | 38.93 | 55 | 2.5 |

| BXNK150-125-400A | 1450 | 182 | 50.56 | 41 | 68 | 29.94 | 37 | 2.5 |

| BXNK150-125-400B | 1450 | 165 | 45.83 | 34 | 67 | 22.82 | 30 | 2.5 |

| BXNK200-150-250 | 1450 | 400 | 111.11 | 20 | 79 | 27.59 | 37 | 2.8 |

| BXNK200-150-250A | 1450 | 363 | 100.83 | 16.5 | 79 | 20.66 | 30 | 2.8 |

| BXNK200-150-315 | 1450 | 400 | 111.11 | 32 | 79 | 44.15 | 55 | 3.5 |

| BXNK200-150-315A | 1450 | 363 | 100.84 | 25.5 | 77 | 32.76 | 45 | 3.5 |

| BXNK200-150-315B | 1450 | 329 | 91.39 | 21.6 | 76 | 25.48 | 37 | 3.5 |

| BXNK200-150-400 | 1450 | 400 | 111.11 | 50 | 78 | 69.87 | 90 | 3.5 |

| BXNK200-150-400A | 1450 | 363 | 100.83 | 41 | 76 | 53.36 | 75 | 3.5 |

| BXNK200-150-400B | 1450 | 329 | 91.39 | 33.8 | 75 | 40.4 | 55 | 3.5 |

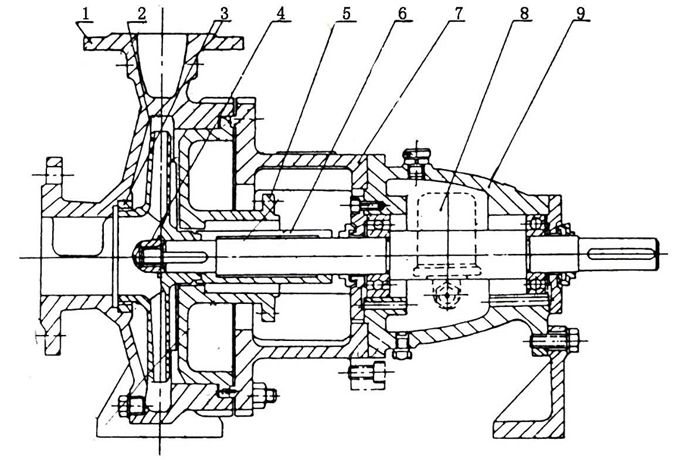

| 1 | 泵体 | 2 | 叶轮 | 3 | 密封环 | 4 | 叶轮螺母 | 5 | 泵盖 |

| 6 | 密封部件 | 7 | 中间支架 | 8 | 轴 | 9 | 悬架部件 | ||

| 序 号 | 泵型号 | 泵外形尺寸 | 泵底板及安装尺寸 | ||||||||||||||||

| a | f | h1 | h2 | b | p1 | p2 | ml | m2 | nl | n2 | n3 | n4 | tl | t2 | w | s1 | s2 | ||

| 1 | 50-32-160 | 80 | 385 | 132 | 160 | 50 | 118 | 128 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 2 | 50-32-200 | 80 | 385 | 160 | 180 | 50 | 139 | 147 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 3 | 65-50-160 | 80 | 385 | 132 | 160 | 50 | 121 | 136 | 100 | 70 | 240 | 190 | 110 | 160 | 12 | 6 | 285 | 14 | 14 |

| 4 | 65-40-200 | 100 | 385 | 160 | 180 | 50 | 140 | 151 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 5 | 65-40-250 | 100 | 500 | 180 | 225 | 65 | 166 | 176 | 125 | 95 | 320 | 250 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 6 | 65-40-315 | 125 | 500 | 200 | 250 | 65 | 194 | 200 | 125 | 95 | 345 | 280 | 110 | 160 | 16 | 6 | 370 | 14 | 14 |

| 7 | 80-65-160 | 100 | 385 | 160 | 180 | 50 | 124 | 143 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 8 | 80-50-200 | 100 | 385 | 160 | 200 | 52 | 147 | 161 | 100 | 70 | 265 | 212 | 110 | 160 | 13 | 6 | 285 | 14 | 14 |

| 9 | 80-50-250 | 125 | 500 | 180 | 225 | 65 | 167 | 179 | 125 | 95 | 320 | 250 | 110 | 160 | 15 | 6 | 370 | 14 | 14 |

| 10 | 80-50-315 | 125 | 500 | 225 | 280 | 65 | 204 | 215 | 125 | 95 | 345 | 280 | 110 | 160 | 18 | 6 | 370 | 14 | 14 |

| 11 | 100-65-200 | 100 | 500 | 180 | 225 | 65 | 159 | 183 | 125 | 95 | 320 | 250 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 12 | 100-65-250 | 125 | 500 | 200 | 250 | 80 | 180 | 201 | 160 | 120 | 360 | 280 | 110 | 160 | 16 | 6 | 370 | 18 | 14 |

| 13 | 100-65-315 | 125 | 530 | 225 | 280 | 80 | 210 | 228 | 160 | 120 | 400 | 315 | 110 | 160 | 18 | 6 | 370 | 18 | 14 |

| 14 | 100-80-160 | 100 | 500 | 160 | 200 | 65 | 132 | 160 | 125 | 95 | 280 | 212 | 110 | 160 | 14 | 6 | 370 | 14 | 14 |

| 15 | 125-80-400 | 125 | 530 | 280 | 355 | 80 | 261 | 279 | 160 | 120 | 435 | 355 | 110 | 160 | 20 | 6 | 370 | 18 | 14 |

| 16 | 125-100-200 | 125 | 500 | 200 | 280 | 80 | 175 | 210 | 160 | 120 | 360 | 280 | 110 | 160 | 17 | 6 | 370 | 18 | 14 |

| 17 | 125-100-250 | 140 | 530 | 225 | 280 | 80 | 193 | 225 | 160 | 120 | 400 | 315 | 110 | 160 | 18 | 6 | 370 | 18 | 14 |

| 18 | 125-100-315 | 140 | 530 | 250 | 315 | 80 | 224 | 250 | 160 | 120 | 400 | 315 | 110 | 160 | 19 | 6 | 370 | 18 | 14 |

| 19 | 125-100-400 | 140 | 530 | 280 | 355 | 100 | 265 | 287 | 200 | 150 | 500 | 400 | 110 | 160 | 20 | 6 | 370 | 18 | 14 |

| 20 | 150-125-250 | 140 | 530 | 250 | 355 | 80 | 204 | 244 | 160 | 120 | 400 | 315 | 110 | 160 | 19 | 6 | 370 | 18 | 14 |

| 21 | 150-125-315 | 140 | 530 | 280 | 355 | 100 | 236 | 271 | 200 | 150 | 500 | 400 | 110 | 160 | 20 | 6 | 370 | 22 | 14 |

| 22 | 150-125-400 | 140 | 530 | 315 | 400 | 100 | 273 | 301 | 200 | 150 | 500 | 400 | 110 | 160 | 21 | 6 | 370 | 22 | 14 |

| 23 | 200-150-315 | 160 | 670 | 315 | 400 | 82 | 255 | 304 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 24 | 200-150-400 | 160 | 670 | 315 | 450 | 82 | 291 | 330 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 25 | 250-200-315 | 180 | 670 | 315 | 450 | 82 | 278 | 344 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 26 | 250-200-400 | 180 | 670 | 380 | 450 | 82 | 314 | 367 | 200 | 150 | 515 | 450 | 140 | 180 | 25 | 10 | 500 | 22 | 18 |

| 序 号 | 泵型号 | 进水法兰尺寸 | 出水法兰尺寸 | 轴伸端尺寸 | 重量 (kg) | |||||||||||

| D1 | D2 | D3 | kl | dl | D4 | D5 | D6 | k2 | d2 | D | L | E | G | |||

| 1 | 50-32-160 | 50 | 125 | 165 | 4 | 18 | 32 | 100 | 140 | 4 | 18 | 24 | 50 | 8 | 20 | 40 |

| 2 | 50-32-200 | 50 | 125 | 165 | 4 | 18 | 32 | 100 | 140 | 4 | 18 | 24 | 50 | 8 | 20 | 48 |

| 3 | 65-50-160 | 65 | 145 | 185 | 4 | 18 | 50 | 125 | 165 | 4 | 18 | 24 | 50 | 8 | 20 | 42 |

| 4 | 65-40-200 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 24 | 50 | 8 | 20 | 50 |

| 5 | 65-40-250 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 32 | 80 | 10 | 27 | 72 |

| 6 | 65-40-315 | 65 | 145 | 185 | 4 | 18 | 40 | 110 | 150 | 4 | 18 | 32 | 80 | 10 | 27 | 82 |

| 7 | 80-65-160 | 80 | 160 | 200 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 24 | 50 | 8 | 20 | 48 |

| 8 | 80-50-200 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 24 | 50 | 8 | 20 | 54 |

| 9 | 80-50-250 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 32 | 80 | 10 | 27 | 75 |

| 10 | 80-50-315 | 80 | 160 | 200 | 8 | 18 | 50 | 125 | 165 | 4 | 18 | 32 | 80 | 10 | 27 | 90 |

| 11 | 100-65-200 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 32 | 80 | 10 | 27 | 73 |

| 12 | 100-65-250 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 32 | 80 | 10 | 27 | 82 |

| 13 | 100-65-315 | 100 | 180 | 220 | 8 | 18 | 65 | 145 | 185 | 4 | 18 | 42 | 110 | 12 | 37 | 120 |

| 14 | 100-80-160 | 100 | 180 | 220 | 8 | 18 | 80 | 160 | 200 | 8 | 18 | 32 | 80 | 10 | 27 | 70 |

| 15 | 125-80-400 | 125 | 210 | 250 | 8 | 18 | 80 | 160 | 200 | 8 | 18 | 42 | 110 | 12 | 37 | 168 |

| 16 | 125-100-200 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 32 | 80 | 10 | 27 | 88 |

| 17 | 125-100-250 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 130 |

| 18 | 125-100-315 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 138 |

| 19 | 125-100-400 | 125 | 210 | 250 | 8 | 18 | 100 | 180 | 220 | 8 | 18 | 42 | 110 | 12 | 37 | 178 |

| 20 | 150-125-250 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 134 |

| 21 | 150-125-315 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 167 |

| 22 | 150-125-400 | 150 | 240 | 285 | 8 | 22 | 125 | 210 | 250 | 8 | 18 | 42 | 106 | 12 | 37 | 186 |

| 23 | 200-150-315 | 200 | 295 | 340 | 12 | 22 | 150 | 240 | 285 | 8 | 22 | 60 | 110 | 18 | 53 | 228 |

| 24 | 200-150-400 | 200 | 295 | 340 | 12 | 22 | 150 | 240 | 285 | 8 | 22 | 60 | 110 | 18 | 53 | 285 |

| 25 | 250-200-315 | 250 | 355 | 405 | 12 | 26 | 200 | 295 | 340 | 12 | 22 | 60 | 110 | 18 | 53 | 264 |

| 26 | 250-200-400 | 250 | 355 | 405 | 12 | 26 | 200 | 295 | 340 | 12 | 22 | 60 | 110 | 18 | 53 | 335 |

1、泵的安装是否合理,对泵的正常运行和使用寿命有很重要的影响,所以安装前必须仔细校正,不得草率,泵的外形及安装尺寸,详见困5和表4。

2、必须保证泵在工作时不超过其允许汽蚀余量。泵的吸上高度《或倒灌高度)必须根据泵的汽蚀余量特性,管路阻力损失特性及高温水的吸入液面压力来确定。

泵吸上使用情况下,应在吸入管路上装上底阀,并在出口管路上设置壤液螺孔或阀门,以供起动前灌泵之用;

泵倒灌使用情况下,应在吸入管路上装上阀门和过滤器,以免杂物进入。

3、吸入和吐出管路应该另有支架,不能用泵作支承。

4、安装泵的地点,应便于巡回检查和检修。

5、安装顺序

① 将机组放在埋有地脚螺栓的基础上,在底座和基础之间放置成对的楔垫作找正之用。

② 松开联轴器。用水平仪分别放在泵轴或底座上,通过调整禊垫,找正机组的水平后,适当拧紧地脚螺栓,以防走动。

③ 用混凝土灌注底座和地脚螺检孔。

④ 待混凝土干涸后,应拧紧地脚螺栓,^并重新检查泵轴的氷平度。

⑤ 在接好管路及确定原动机转动方向以后,接上联轴器,再核对一遍轴的同心度,测量联轴器的外园上下,左右的差异不得超过0.1mm,两联轴器端面间隙,在一周内最大和最小的间咪差不得超过0.3mm.

⑥ 在机组实际运行3—4小时后作最后检查,如无不良现象,则认为安装合格。